Share this post

How are Hillebrand flexitanks recycled?

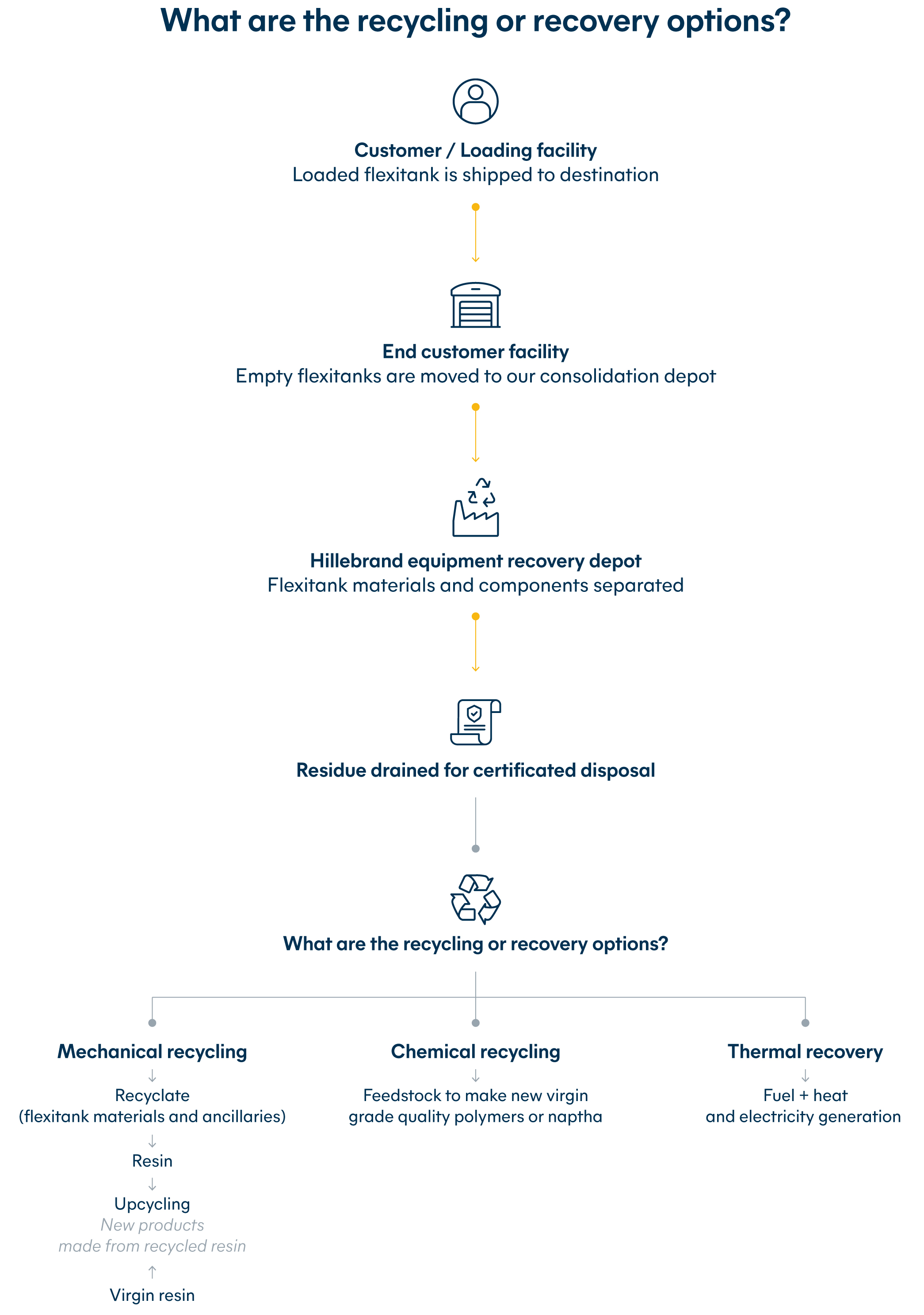

Hillebrand’s flexitanks are designed with circularity in mind and manufactured in-house from a high grade 100% virgin grade polyethylene (LLDPE) film - 100% recyclable. The company offers a full door-to-door logistics service including a customised global solution for the recovery and recycling of used flexitanks.

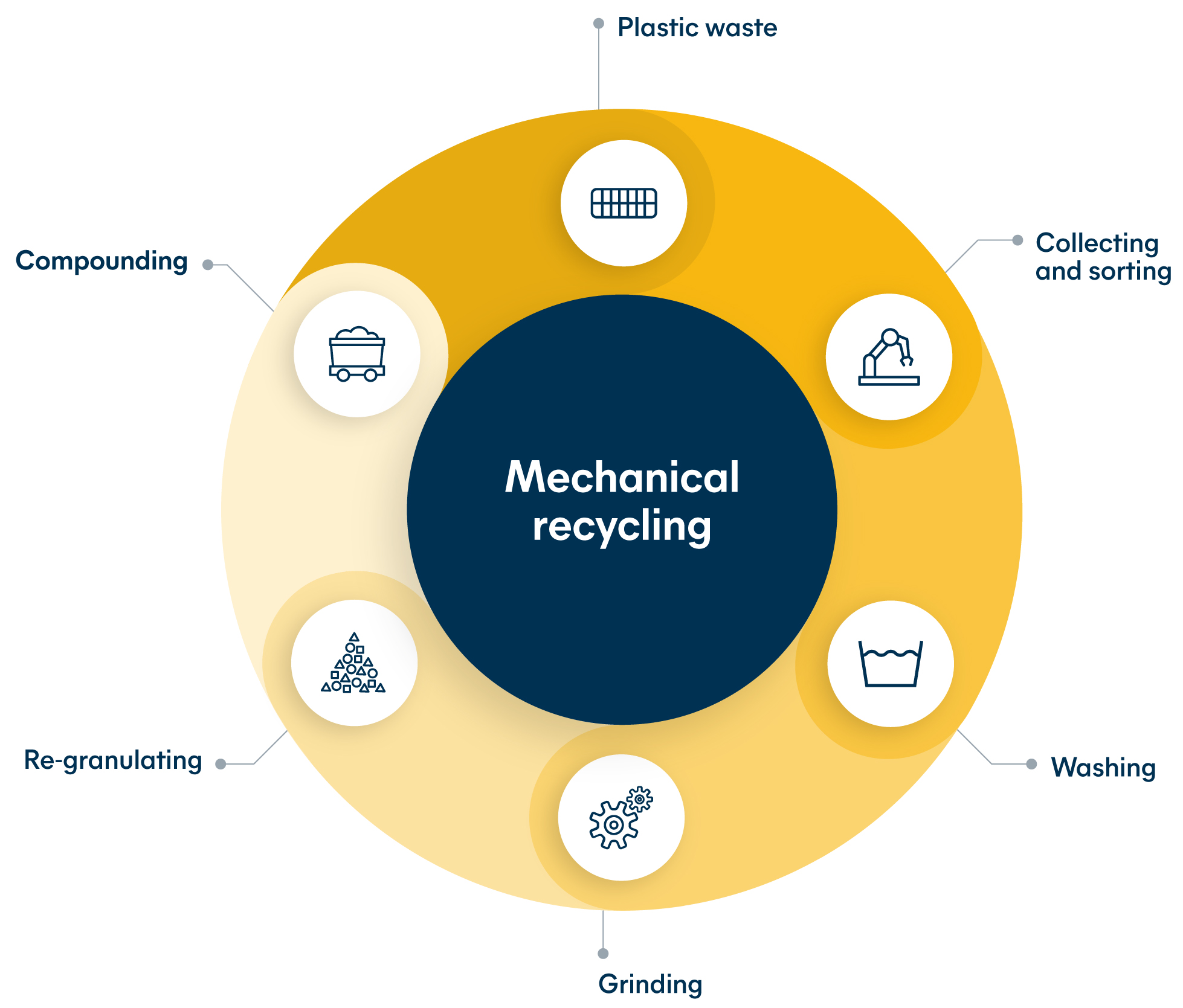

Mechanical recycling

Ideal for flexitanks that have transported wine and some food products or other products which facilitate easier cleaning of the flexitank material. Plastics are recovered and reprocessed into secondary raw materials for manufacture of new products.

Resin produced from the recycling of our flexitanks can be used to manufacture:

- Construction Film for building industry

- Refuse or Garment bags

- Plastic piping / Plastic Wood

The benefit of mechanical recycling is that it preserves 70% of the used energetic value (compared to a one time thermal recovery).

Chemical recycling or “Advanced recycling”

Being recognised as a complement to mechanical recycling for higher quality plastic waste, there are 2 main forms:

- Depolymerisation: breaking down polymers into their monomers for use as a feedstock to make new virgin grade quality polymers

- Pyrolysis: turning mixed plastic waste into either a naphtha to make fuel or new polymers

1 ton of plastics waste processed by Energy Recovery generates 1.8 tons of CO2 compared to Advanced Recycling generating 0.4 tons of CO2.

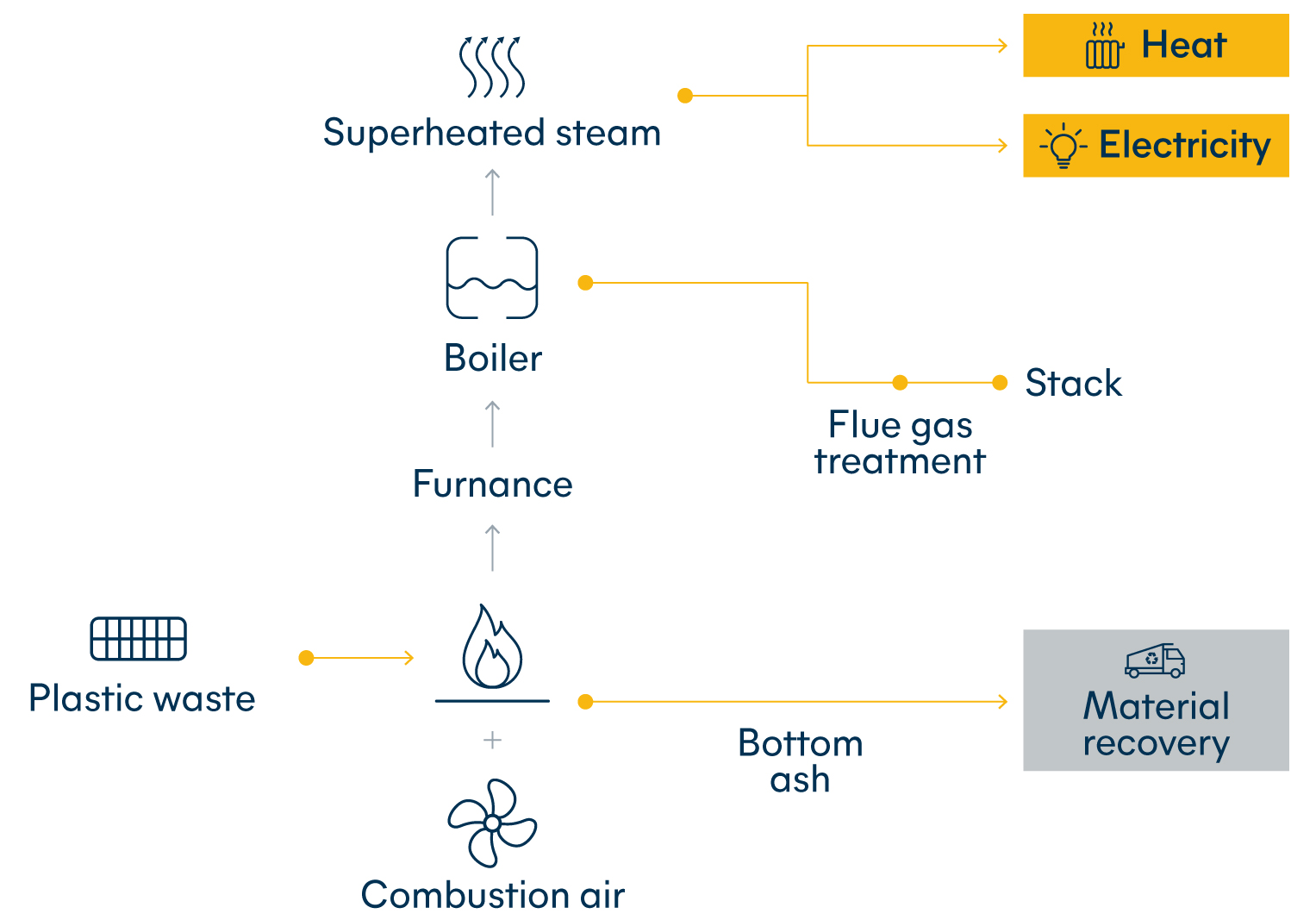

Energy Recovery or Thermal Recovery

A resource recovery method converting waste material into useable heat, electricity, or fuel through a variety of methods including combustion, gasification to generate heat or electricity. This is used when it is not economically viable to remove the product surface residue from the flexitank material due to the nature and content of the liquid shipped. Industrial oils would generally fall into this category.

How is the recycling method determined?

This does depend on 3 key elements:

- Location: legislation governing the recycling of used plastics in any given country will determine best recovery method as well as the available recycling infrastructure.

- Volume: the higher the volume of empty flexitanks in any one location the more favourable the economies of scale to set up the infrastructure.

- Product shipped: depending upon how easy it is to remove the residue and clean the material surface, will determine the best method of recycling or recovery.

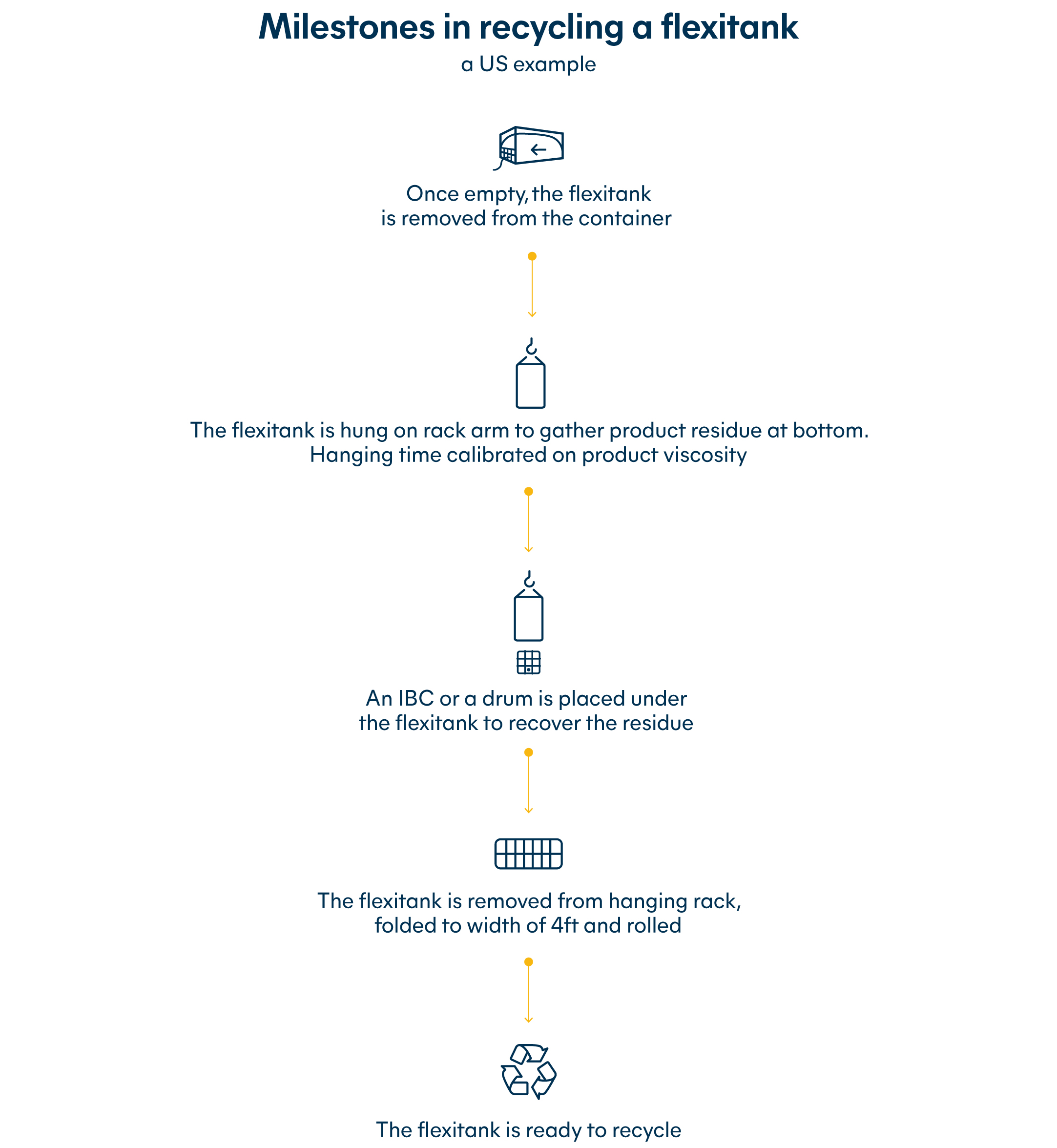

Hillebrand can provide a local and customised flexitank recovery and residue disposal service immediately after discharge of the product. Hillebrand will arrange for the empty flexitanks to be returned to our nearest depot for removal, draining and preparation for collection by an authorised and certificated local waste management company.

Let’s all work together to make the world a cleaner place.