Share this post

Shipping ready-packed goods or in bulk. Our tips to help you choose which is best for you

The rippling effect of the global container imbalance caused by the Covid-19 pandemic sees the future of world trade at a pivotal moment. Consumer demands and habits have changed and as a result, producers and buyers are also changing; the viability of current markets, routes to market and moreover the performance of the supply chain for those markets are all under scrutiny.

The nature of the product you ship can sometimes limit your freight options

Though for many global buyers and sellers there are two options of container shipping, packaged at origin, palletized and shipped, or shipped in bulk, through the use of flexitanks or ISO tanks for packaging at destination.

But, how do you choose which one is right for you? Here’s some things to consider…

Making the most of you money

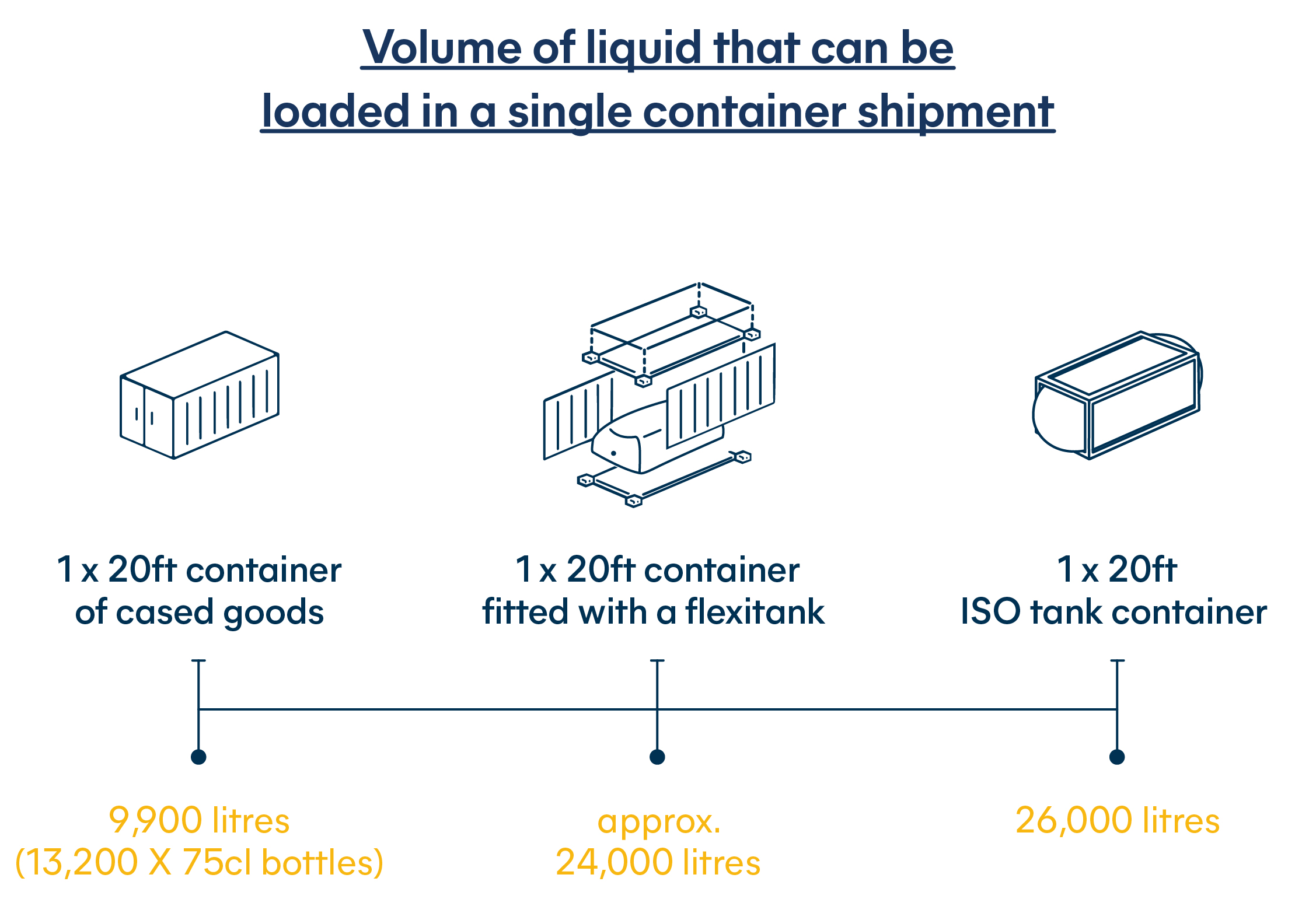

Most commonly discussed and recognised as a benefit of full container load shipping in bulk compared to packaged goods shipping, is the volume of liquid that can be loaded in a single container shipment:

So in terms of cost saving, by shipping in bulk you’ll be transporting the equivalent of two 20ft containers of product for around the price of one.

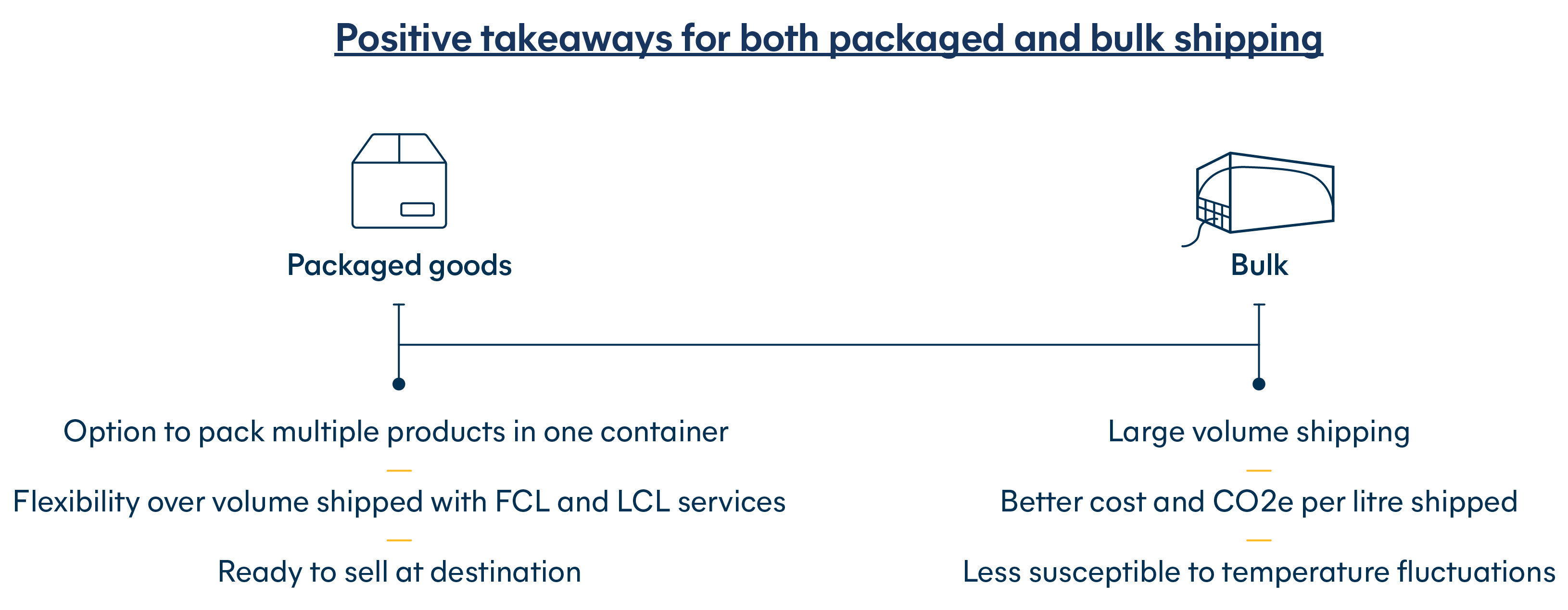

Bulk liquid logistics therefore out shines packaged goods shipping when talking about the amount of volume that can be transported. But, it only allows you to transport one product. Packaged shipping gives you the option to move multiple products in one container. Moreover, you have flexibility over volumes shipped. Take a look at our article on groupage vs full load shipping and you’ll see an array of benefits for shipping in smaller packed volumes. So, what about storing these volumes?

In-market storage and sale

ISO tanks and flexitanks can be used to store the product they carry, which many are not aware of. Hillebrand flexitanks can be stored in and out of a container, depending on the environment and length of storage required. So in this instance, the footprint in storage cost can be less in comparison to a full container of pallets. It’s a lot to consider and compare isn’t it! Let’s keep going…

Packaging in-market could also provide sellers with more flexibility to meet changing consumer demands and respond quicker with different packaging formats. It’s also easier to control the quality of the packaging presented to end customer, as the possibility of damage is far smaller compared to final format packing at origin.

But while in-market packaging has these advantages, ready packed goods can give you the option to change product range faster, since the overall quantity shipped and needing to be sold is lower. Packaging at origin, also gives the product owner a better degree of control over the conditions under which their goods packed and the quality of the materials used.

Product quality

In terms of actual transport, from origin to destination, bulk shipping could be considered less risky than packaged goods shipping in a dry container. Why? A larger single volume of liquid has a greater thermal inertia than a smaller one. Meaning it is less prone to experience large temperature variations during transit. Think of it this way, what warms up quicker in the sun, your beer or your swimming pool? Whichever method you choose, be it ready packaged goods or bulk, both have options to safeguard product quality. For packaged goods check out our insulation liners and for bulk shipping there are flexitanks in our range that include barrier technology against factors like oxidisation.

It is important on this point to also consider the nature of what is being shipped. Wine for example can be shipped both cased or bulk, but some wines need to be aged in bottle and therefore bulk shipping is not a viable option for every wine product.

The reuse of equipment is also an important consideration, when we put our green hat on and turn our thoughts to the environmental impact of global logistics, both packaged and bulk.

Impact on the environment

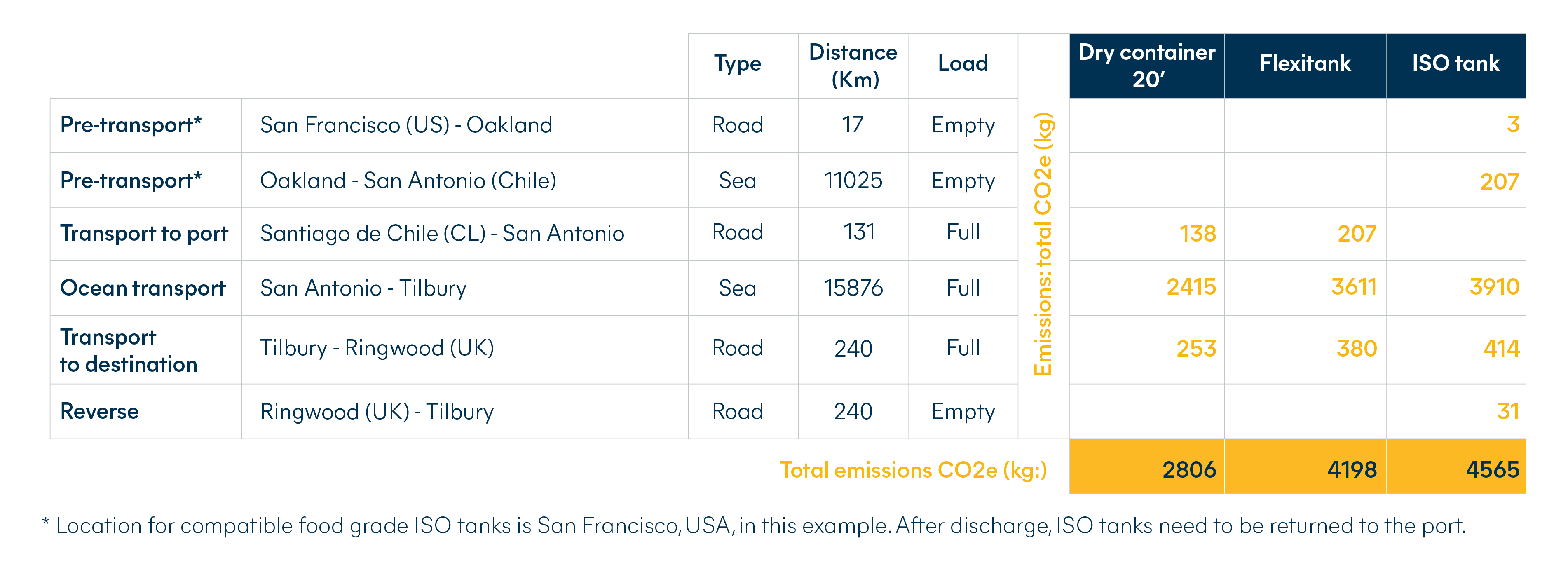

Hillebrand research shows, based on a 20ft container, a flexitank reduces emissions per litre by -38% compared to cased goods on the same routing:

Other research carried out by Carbon Footprint Ltd also show that the emissions during the whole life circle are lower for flexitanks compared to ISO tanks.

With ready packed goods, you also need to deliberate on the amount of packaging in the container and if it is recyclable. For ISO tanks, the entire tank can be reused and even though a flexitank is single use, it can be recycled. If you want to know more about the sustainability of our flexitanks, take a look here.

If you’re still undecided or need help making the right choice for you, speak to your local office. We’re here to help.

-ebook-1---global-freight-forwarding/hil---cta-text-1---ebook-global-freight-forwarding-(1).png?sfvrsn=a2292c3e_3)

-ebook-1---global-freight-forwarding/hil---cta-post---yellow.jpg?sfvrsn=5e55bfc5_2)